Further processing

We bring your order into top condition

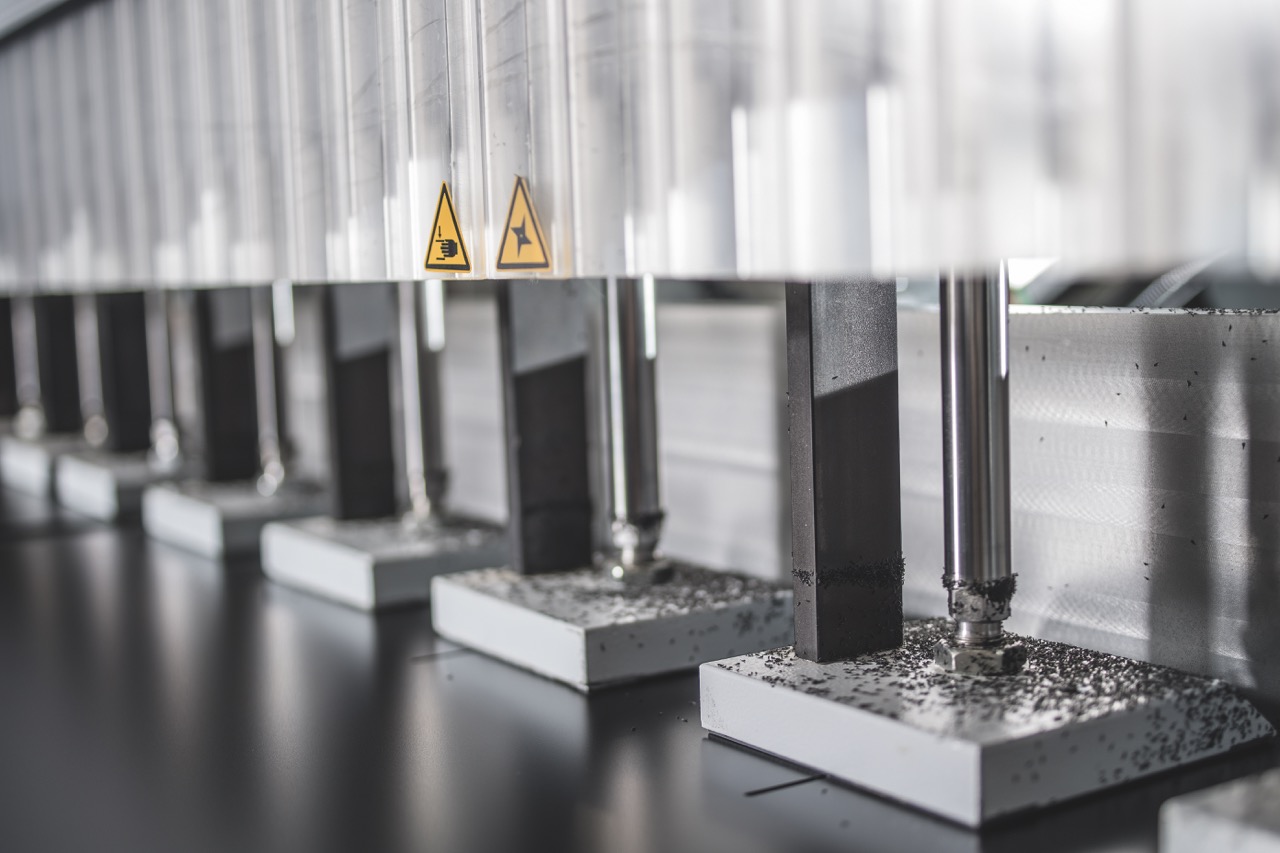

Milling

We process panel material up to a size of 1800 x 3000 mm. The machine is equipped with an optical recognition system and guarantees exact and precise processing.

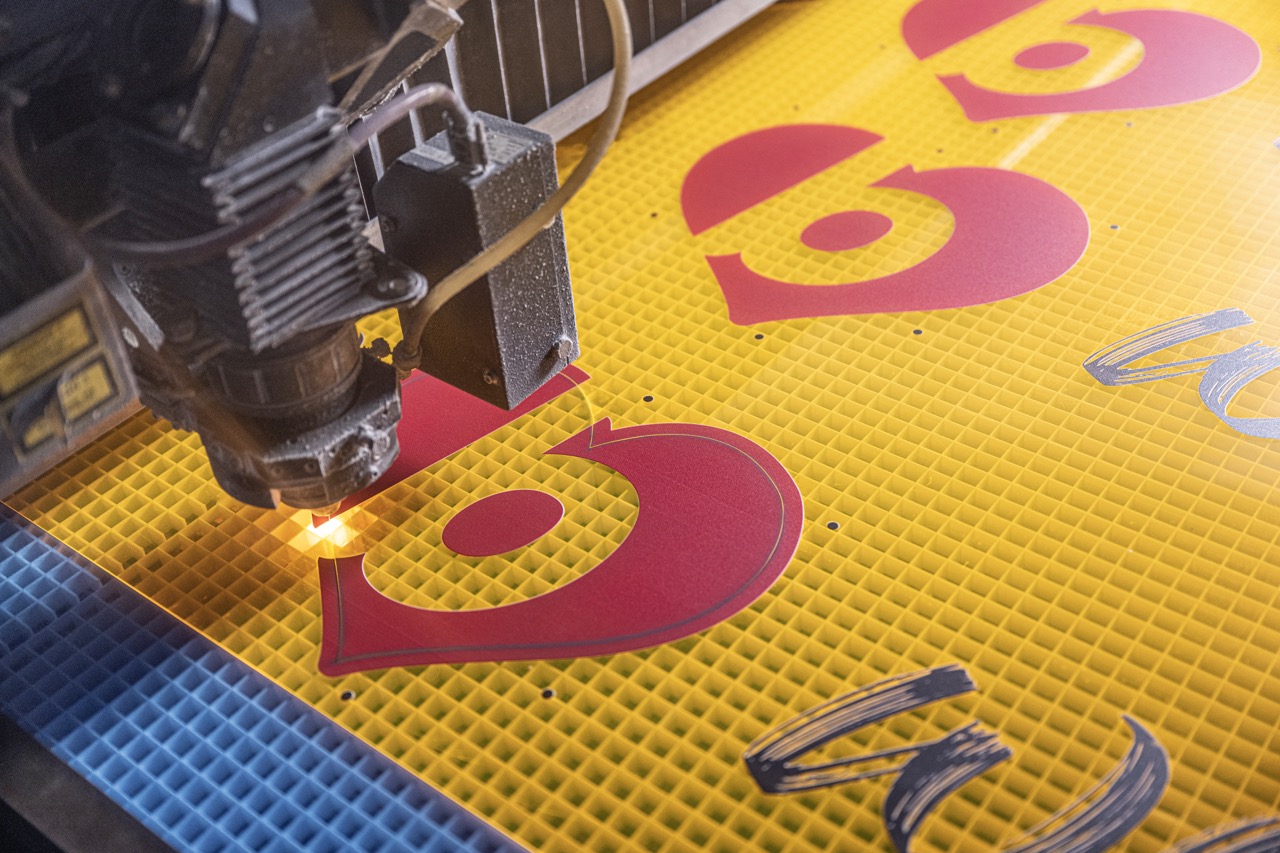

Laser Treatment

Our Eurolaser machine cuts and engraves acrylics/PMMA in one single operation. Laser technology provides highly transparent cutting edges with inner and outer contours equally high in edge quality. Other possible areas of application: plastic foils, keyboard foils, cardboard, cork, wood, verneer, inlays, multiplex, MDF, etc.

Diamond polishing

With help of Euracryl ABP 310 and various tools we are able to polish edges in high gloss or matt quality. Different plastic parts up to lengths of 3100 mm can be treated.

A stepless and swiveling unit allows to polish edges with a range of angles of -1° to 48°.

Punching

Skillet (1600 x 1200 mm) or cylinder (700 x 500 mm)

give your product the desired shape using steel rule dies.

Cutting

2 cutting machines: up to 3200 mm in width

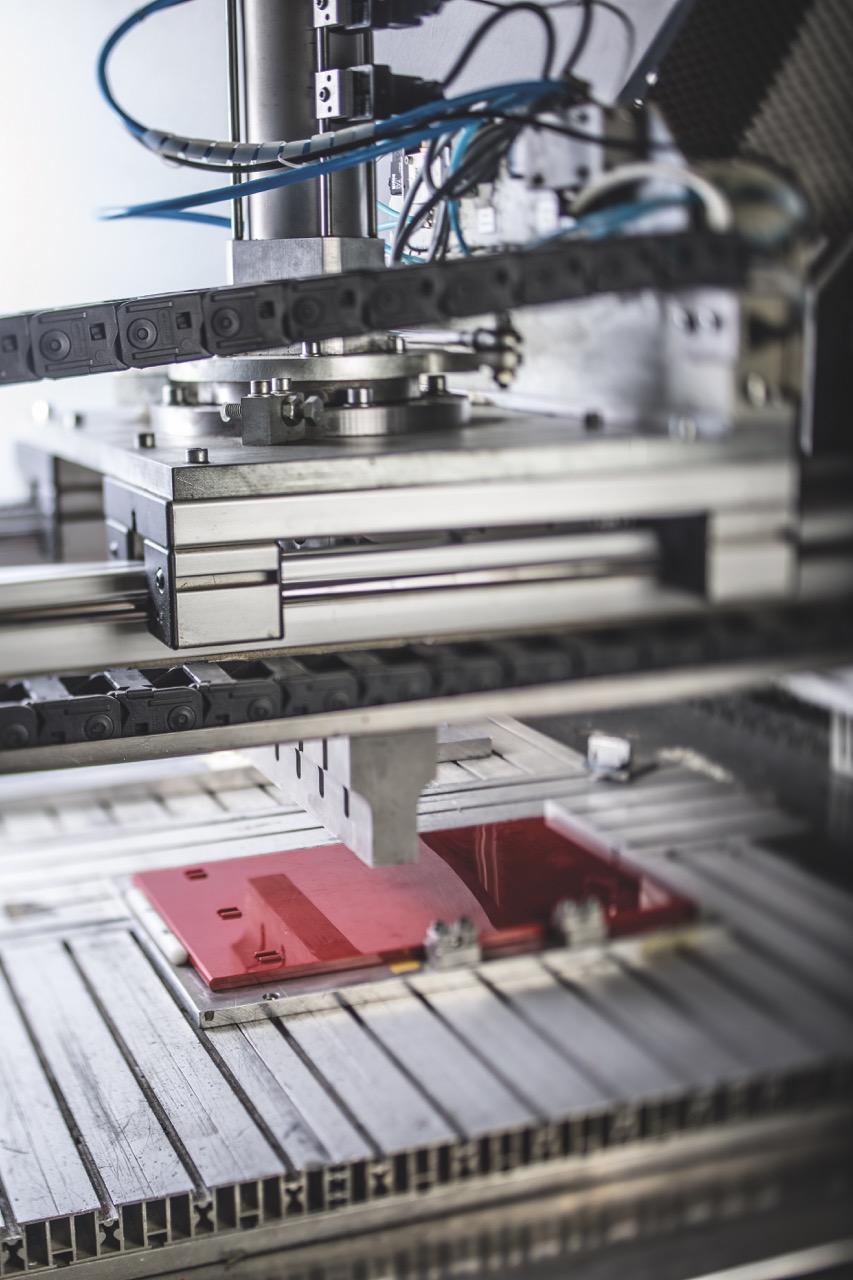

Bending / Trimming

Plastics, such as PMMA, PETG, PS, PVA or PP are heated over heating rods and brought into appropriate geometry. Depending on the material and its thickness,

this is done on various machines, some of which we have developed ourselves.

Gluing

We make sure to select the optimal adhesive for the chosen material to bond plastics together. The criteria of choice include neat processing, consideration of the demands to be met later and an appealing look – profit from our many years of experience.

Plastics injection moulding

With modern computer-operated injection moulding machines we manufacture precise technical components made of various thermoplastic plastics.

Ultrasonic / High frequency welding

Using ultrasonic technology, plastic components made of PS can be welded together neatly. A generator produces electrical oscillations which are converted to mechanical vibrations. Through ultrasonic energy the components in question are plasticized at the joining areas and welded with pressure. In high frequency welding, long wave rays are converted to thermal energy. All PVC components are high frequency welded.

Do you have anymore questions?

We would be happy to advise you on the product selection or on your individual wishes and options for everything to do with POS displays.

Adress:

werba print & display GmbH

Am Froschbächle 23

77815 Bühl (Baden)

Germany

Contact:

Fon +49 (0) 7223 / 9864 - 0

Fax +49 (0) 7223 / 9864 - 30

E-Mail info@werba-print.de